Stainless Steel Pressure Gauge Cock & Accessories

SD GREEN PVT LTD Pressure Gauge Cock Series : VGC01 & VGC03 are having compact & rugged Bar Stock body design & construction, which is installed between Pressure Gauge and Pipe which is used to isolate the Pressure Gauge from the pressure media in order to inspection or replacement of the Gauge where the pressure is continuously pulsating.

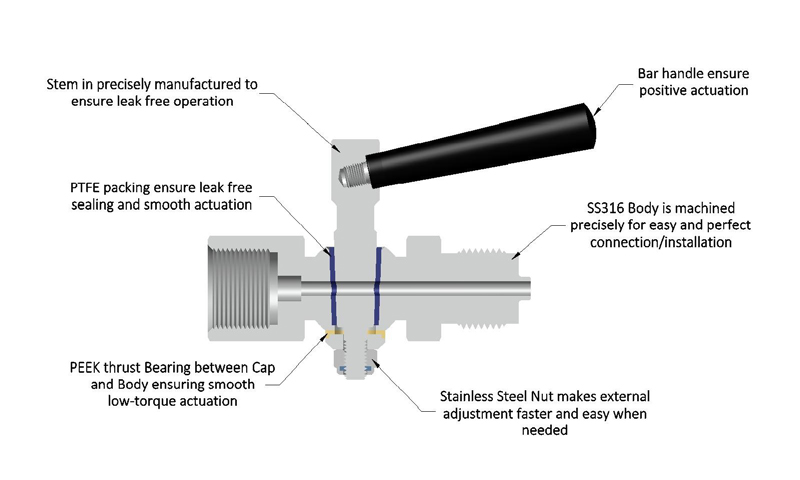

Construction & Features of Pressure Gauge Cock Series : VGC01 & VGC03 (Without Live Load Stem)

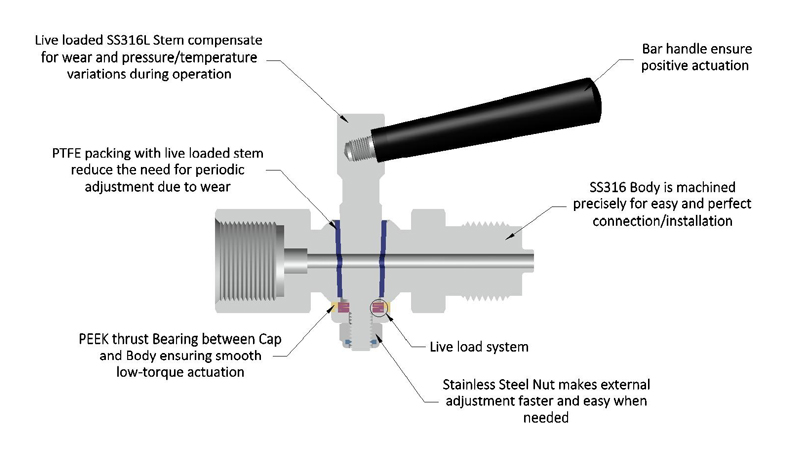

SD GREEN PVT LTD Pressure Gauge Cock Series : VGC11 & VGC13 are having compact, rugged & Live Loaded Stem design & construction, which is installed between Pressure Gauge and Pipe which is used to isolate the Pressure Gauge from the pressure media in order to inspection or replacement of the Gauge where the pressure is continuously pulsating.

Construction & Features of Ball Valves with Live Load PEEK Seat

Features / Benefit :

- Available in Material SS316L.

- Replaceable PTFE Packing design.

- 2 Way design.

- Manufactured from Bar Stock.

- Every Gauge cock is Pressure tested.

Product Range and Operating Parameters :

- Pressure Rating: UPTO 368 PSIG (25 Bar) at CWP

- Temperature Rating: UPTO 100o C

- End Connections :1/4″ to 1/2” Male / Female BSPP / BSPT / NPT Pipe Thread M20 x 1.5 & M20 x 1.5. Metric Threads

Applications :

Shut-off device for pressure measuring Instrumentations for measurement of Liquid, Gases and Vapours.

Note :

Flange type, 3 Way & Customized Pressure Gauge Cock are available on request.

Pressure Gauge Cock & Accessories Includes :

Pressure Gauge Cock, Pressure Gauge Cock with Swivel Nut, Pressure Gauge Cock with Live loaded Stem, Compact Gauge Syphons, Swivel Nut, Gauge Adapters, Female to Male Gauge Adapters, Sealing Washer, Gauge Snubbers, etc.

Type Test Approvals :

The design of SD GREEN PVT LTD Ball Valves Series : VB41 have been tested to Hydrostatic Proof and Burst Test in accordance with MSS SP-99-2016a Clause 5.5 & 5.6.

Testing :

- Standard Test – Each Valve is pressure tested with Nitrogen at 1000 PSIG (69 Bar) for leakage at the seat and packing.

- Optional Hydrostatic Test – This Test is performed with De-ionized water at 1.5 times the working pressure.

Certification :

The Certificate to 3.1 acc. to EN10204 for Valve body material and pressure test will be provided on request.