Twin Ferrule Compression Tube Fittings

SD GREEN PVT LTD has developed high quality Twin Ferrule Compression Tube Fittings to meet the growing demand in the industries such as Petrochemical, Oil & Gas, Semiconductor, Power, Refinery, Nuclear, CNG & other major Industries.

SD GREEN PVT LTD Twin Ferrule Tube Fittings have been carefully designed & manufactured under strict quality assurance procedures meeting the requirements of ISO 9001-2015 & PED 2014/68 EU.

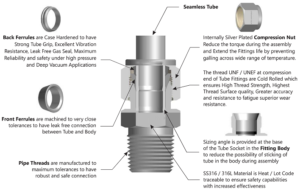

Construction & Unique Features of Twin Ferrule Compression Tube Fittings

Comparison of SD GREEN PVT LTD Tube Fittings :

| FEATURES | SD GREEN PVT LTD |

| Twin Ferrule Design | Yes |

| Traceable Quality SS316 | Yes |

| Silver Plated & Dry Lubricated Nut | Yes |

| Low Torque assembly | Yes |

| Case Hardened Back Ferrule | Yes |

| Thread Design to allow intermix of Components | Same |

| Shoulder Marking to distinguish between Metric & Imperial size | Same |

| Ability to Identity different thread forms through body marking | Same |

| Stringent Quality Assurance Standard | Yes |

| Installation procedures | Same |

| Gaugeability to check correct installation | Same |

| Pressure Rating UPTO 10,000 PSIG (690 bar) | Same |

| Temperature Rating UPTO 538O C | Same |

| Requirement of Tube Specifications | Same |

| Leak integrity | Same |

Type Test :

SD GREEN PVT LTD SS316 Twin Ferrule Tube Fittings have been satisfactorily type tested to ASTM F1387-19 Standard specifications for performance of Piping & Tubing mechanical attached Fittings under witness of M/s. TUV Rheinland are as under :

| • Examination of Test Specimen | Annex : A2 |

| • Pneumatic Proof Test | Annex : A3 |

| • Hydrostatic Proof Test | Annex : A4 |

| • Impulse Test & Repeated Assembly Test | Annex : A5 & A9 |

| • Flexure Fatigue Test & Repeated Assembly Test | Annex : A6 & A9 |

| • Tensile Test | Annex : A7 |

| • Hydrostatic Burst Test | Annex : A8 |

| • Rotary Flex Test | Annex : A10 |

| • Thermal Cycling Test | Annex : S2 |

| • Elevated Temperature Soak Test | Annex : S3 |

| • Vibration Test | Annex : S8 |

Intermix & Interchange Test :

SD GREEN PVT LTD Twin Ferrule Tube Fittings have been Intermixed & Interchanged with Swagelok® Tube Fittings. Following performance test carried out satisfactorily :

| • Pneumatic Proof Test | Annex : A3 |

| • Hydrostatic Proof Test | Annex : A4 |

| • Hydrostatic Burst Test | Annex : A8 |

Product Range and Operating Parameters :

- Pressure Rating: Vacuum to 10,000 PSIG (680 Bar) depending on Material, Size & type of Fittings at CWP.

- Temperature Rating: Cryogenic to 538o C (depending on Material).

- Available Size :

- Fractional : 1/8” to 1” ODT

- Metric : 3mm to 25mm ODT

- End Connections :1/8” to 1” BSPP / BSPT / NPT / SAE Pipe Threads & Butt / Socket Weld Connections.

Applications :

Instrumentation, Alternative Fuel, High Pressure, Deep Vacuum, General Services, etc.

Twin Ferrule Tube Fittings are also known as :

Instrumentation Tube Fittings, Twin Ferrule Tube Fittings, Two Ferrule Tube Fittings, Ferrule Fittings, Compression Tube Fittings, Tube Fittings, Swagelok® Tube Fittings, Swagelok® Fittings, A-Lok® Fittings, Compression Fittings, etc.